WHAT IS THE TIRE SEALANT AND INFLATOR KIT

The kit consists of an air compressor to re-inflate the tire and a canister of sealing compound that effectively seals most punctures. This kit provides a temporary tire repair allowing you to drive your vehicle up to 120 mi (200 km) at a maximum speed of 50 mph (80 km/h) to reach a tire service location.

Note: The temporary mobility kit contains enough sealant compound in the canister for one tire repair only. See an authorized dealer for replacement sealant canisters.

TIRE SEALANT AND INFLATOR KIT PRECAUTIONS

WARNING: Depending on the type and extent of tire damage, some tires can only be partially sealed or not sealed at all. Loss of tire pressure can affect vehicle handling, leading to loss of vehicle control. WARNING: Depending on the type and extent of tire damage, some tires can only be partially sealed or not sealed at all. Loss of tire pressure can affect vehicle handling, leading to loss of vehicle control. WARNING: Do not use the kit on a previously damaged tire, for example when it has been driven under inflated. This could cause loss of vehicle control, personal injury or death. WARNING: Do not use the kit on a previously damaged tire, for example when it has been driven under inflated. This could cause loss of vehicle control, personal injury or death. |

Do not attempt to repair punctures larger than 0.24 in (6 mm) or damage to the tire’s sidewall.

Only punctures located within the tire tread can be sealed with the kit.

Only use the kit supplied with your vehicle.

The temporary mobility kit contains enough sealant compound in the canister for one tire repair only.

After using the sealant, an authorized dealer needs to replace the tire pressure monitoring system sensor and valve stem on the wheel.

LOCATING THE TIRE SEALANT AND INFLATOR KIT

The kit is located under the load floor in the rear of the vehicle.

TIRE SEALANT AND INFLATOR KIT COMPONENTS

| A B C D E F G H I J |

USING THE TIRE SEALANT AND INFLATOR KIT

Tips for use of the kit

To make sure the kit operates safely and properly, observe the following:

- Before operating the kit, make sure your vehicle is safely off the road and away from moving traffic.

- Do not remove any foreign objects, such as nails or screws, from the tire.

- Do not allow the compressor to operate continuously for more than 15 minutes. This prevents the compressor from overheating.

- Only use the kit when the ambient temperature is between -22°F (-30°C) and 158°F (70°C).

- Only use the sealing compound before the use-by date. The use-by date is on a label on the sealant canister and can be seen through the rectangular viewing window on the bottom of the compressor. Check the use-by date regularly and replace the canister when the sealant expires.

Note: Sealant compound contains latex. Use appropriate precautions to avoid any allergic reactions.

Place the selector in the Air position when inflating a tire or other objects. Place the selector in the Air position when inflating a tire or other objects. |

What to do when a tire is punctured

A tire puncture within the tire’s tread area can be repaired in two stages with the kit.

- In the first stage, the tire is reinflated with a sealing compound and air. After the tire has been inflated, drive the vehicle a short distance approximately 4 mi (6 km) to distribute the sealant in the tire.

- In the second stage, check the tire pressure and adjust, if necessary, to the vehicle’s specified tire inflation pressure.

First Stage: Reinflating the Tire with sealing compound and air

WARNING: Do not stand directly over the kit while inflating the tire. If you notice any unusual bulges or deformations in the tire’s sidewall during inflation, stop and call roadside assistance. WARNING: Do not stand directly over the kit while inflating the tire. If you notice any unusual bulges or deformations in the tire’s sidewall during inflation, stop and call roadside assistance. WARNING: If the tire does not inflate to the recommended tire pressure within 15 minutes, stop and call roadside assistance. WARNING: If the tire does not inflate to the recommended tire pressure within 15 minutes, stop and call roadside assistance. |

Park the vehicle in a safe, level and secure area, away from moving traffic.

Turn the hazard lights on. Apply the parking brake and power off the vehicle. Inspect the flat tire for visible damage.

If a puncture is located in the tire sidewall, stop and call roadside assistance.

- Remove the valve cap from the tire valve.

- Unwrap the dual purpose hose (black tube) from the back of the compressor housing.

- Fasten the hose to the tire valve by turning the connector clockwise. Tighten the connection securely

- Plug the power cable into the 12-volt power point in the vehicle.

- Remove the warning sticker found on the casing/housing and place it on the top of the instrument panel or the center of the dash.

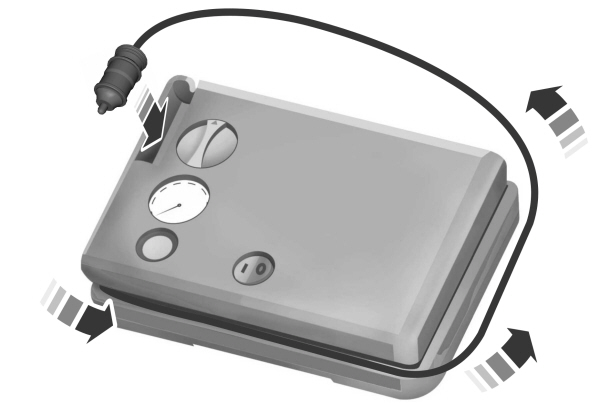

- Turn dial (A) clockwise to the sealant position. Turn the kit on by pressing the on/off button (B).

- Inflate the tire to the pressure listed on the tire label located on the driver door or the door jamb area. Check the final tire pressure with the compressor turned off to get an accurate pressure reading.

- When the recommended tire pressure is reached, turn off the kit, unplug the power cable, and disconnect the hose from the tire valve. Re-install the valve cap on the tire valve and return the kit to the rear of the vehicle.

- Drive the vehicle 4 mi (6 km) to distribute the sealant evenly inside the tire.

Note: If you experience any unusual vibration, ride disturbance or noise while driving, reduce your speed until you can safely pull off to the side of the road to call for roadside assistance. Do not proceed to the second stage of this operation.

Second Stage: Checking the tire pressure with the inflator kit

WARNING: If the tire does not inflate to the recommended tire pressure within 15 minutes, stop and call roadside assistance. WARNING: If the tire does not inflate to the recommended tire pressure within 15 minutes, stop and call roadside assistance. WARNING: The power plug may get hot after use and should be handled carefully when unplugging. WARNING: The power plug may get hot after use and should be handled carefully when unplugging. |

Check the air pressure of your tires as follows:

- Remove the valve cap from the tire valve.

- Firmly screw the air compressor hose onto the valve stem by turning clockwise.

- Push and turn the dial clockwise to the air position.

- If required, turn on the compressor and adjust the tire to the recommended inflation pressure.

- Unplug the hoses, re-install the valve cap on the tire and return the kit to the rear of the vehicle.

What to do after the tire has been sealed

After using the kit to seal your tire, replace the sealant canister. Sealant canisters and spare parts can be obtained at an authorized dealer. Empty sealant canisters may be disposed of at home. However, canisters still containing liquid sealant should be disposed of in accordance with local waste disposal regulation.

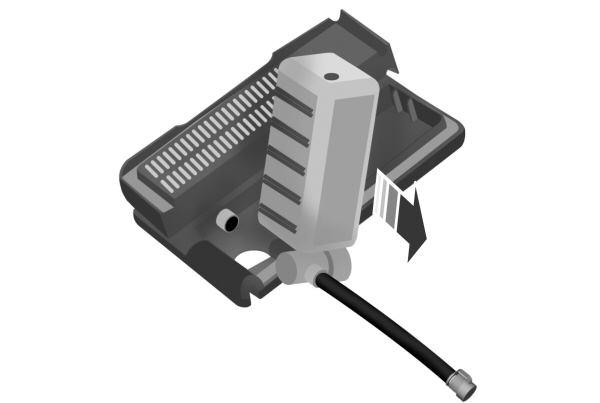

Removal of the sealant canister from the kit

- Unwrap the dual purpose hose (black tube) from the compressor housing.

- Unwrap the power cord.

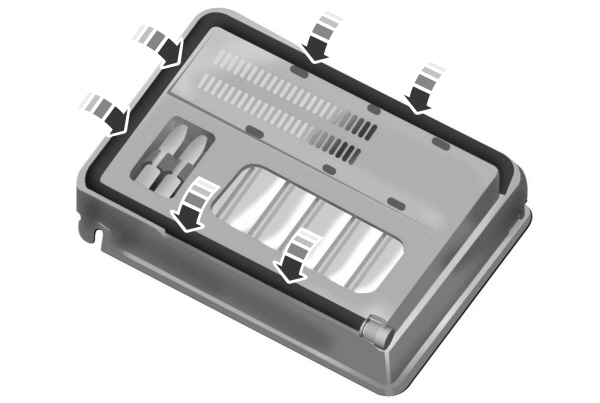

- Remove the back cover.

- Rotate the sealant canister up 90 degrees and pull away from casing/housing to remove.

Installation of the sealant canister to the kit

- With the canister held perpendicular to the housing, insert the canister nozzle into the connector and push until seated.

- Rotate the canister 90 degrees down into the housing/casing.

- Snap the back cover back into place.

- Wrap the dual purpose hose (black tube) around the channel on the bottom of the housing/casing.

- Wrap the power cord around the housing and stow the accessory power plug.